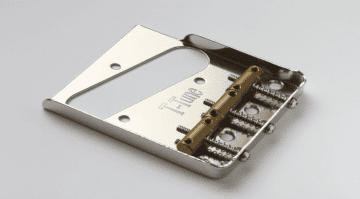

The Heraeus AMLOY: A new 3D-printed guitar bridge!

3D printing seems to be quite a trend in guitar gear. We recently wrote a mircotonal guitar gadget made using 3D printing and Lego bricks. Now the new Heraeus AMLOY is the world’s first 3D-printed bridge made out of metal. Using a clever “bionic structure”, the bridge increases string vibrations to the instrument, while remaining scratch and corrosion resistant. Let’s dive in!

Bionic structure

The new Heraeus AMLOY was designed using the development and processing of amorphous metals. It might sound a bit Terminator 2, but what it basically means is that the AMLOY bridge was made using a special type of 3D metal printing using a unique alloy. And because it is 3D-printed, it’s not just a solid block of metal, but instead has an intricate honeycomb ‘bionic structure’, one that conventional guitar-building tools could not have produced. Apparently this lets the bridge transmit vibrations more efficiently from the strings to the instrument, without compromising the strength and integrity of the structure.

“One could also imitate the sound of other metals by changing the structures inside the bridge … A bridge made of amorphous metal would then sound like a bridge made of brass, for example. The difference is that due to its elasticity it keeps the sound longer, does not wear out and still looks like new even after years.” – Heraeus AMLOY head Jürgen Wachter

Amorphous metals

Amorphous metals have a host of unique properties, and are formed by putting molten metal through a shock freezing process. According to the company’s site, the atoms in amorphous metals have no opportunity to form a crystalline lattice and solidify in a disordered manner. This means that the resulting material ends up being particularly elastic while at the same time also being very strong.

Built to last

Due to the nature of their structure, amorphous metals are also scratch- and corrosion-resistant, according to Heraeus. They are also biocompatible, which means there is no chemical reaction when they make contact with biomaterials. According to Wachter, “unlike nickel-plated aluminium bridges, [the AMLOY is] also suitable for allergy sufferers.”

A well-respected luthier and maker of stunning instruments, Nik Huber of Nik Huber Guitars has already tried the AMLOY bridge on one of his guitars and considers it an exciting next step in guitar building. And Huber knows a thing or two about crafting fine instruments.

I love it when new technologies collide with traditional guitar manufacturing, and with the advent of 3D-printing, I expect to see a lot of new and interesting ways of making instrument hardware.

More Information

- Heraeus AMLOY 3D-printed bridge: Heraeus AMLOY

- Heraeus AMLOY metal 3D-printed bridge: Heraeus AMLOY