Lehle Interview: Signal Flow Made in Germany.

How a German Company Is Cleaning Up Signal Paths

As I mentioned in my highlights for 2025: I had the opportunity to delve into the intricacies of technical features and speak with Burkhard Lehle of Lehle GmbH. We discussed signal loss, the drawbacks of custom-made products, and how his company got its start.

Table of Contents

Lehle is a German manufacturer of signal routing solutions for guitars, basses, and other instruments. The company is based in Voerde on the Lower Rhine. The company specializes in products that address an area where many guitarists lose their sound without noticing: the signal flow between the instrument, effects, and amplifier.

Rather than developing classic effects devices, Lehle creates tools that preserve the sound without altering it – technically sober yet musically effective. This is probably also the reason why I only found out about the company so late; far too many flashy overdrives, fuzz boxes, and the like caught my attention.

Engineering Expertise Instead of Sound Myths!

Burkhard Georg Lehle founded Lehle after studying music and physics and working as a guitar and amplifier technician for many years. This background continues to influence the brand, as you will learn from the interview below.

Lehle’s products are not created based on trends or marketing narratives, but rather on specific problems that arise in real rigs, such as ground loops, signal loss, and unreliable switching mechanisms. Lehle is known for its consistent use of durable technologies, such as gold contact relays, Hall sensors, VCAs, and specially developed high-impedance transformers.

The goal is always the same: a stable, unadulterated signal, no matter how complex the setup.

Technology that Delivers Measurable Results

The approach pursued by Lehle is not only subjectively convincing, as is evident in a direct comparison.

In an independent video test on the Vertex Effects channel, various volume pedals were compared, and Lehle was the clear winner among the active pedals. The sound fidelity, clean separation of the signal paths, and high build quality of the Mono and Stereo versions received particular praise. These aspects cannot be explained by marketing, but they can be measured and heard.

In an environment where many solutions seem similar, Lehle stands out because its technical decisions are based on comprehensible reasoning, and the results are audible.

Made in Germany – Out of Conviction

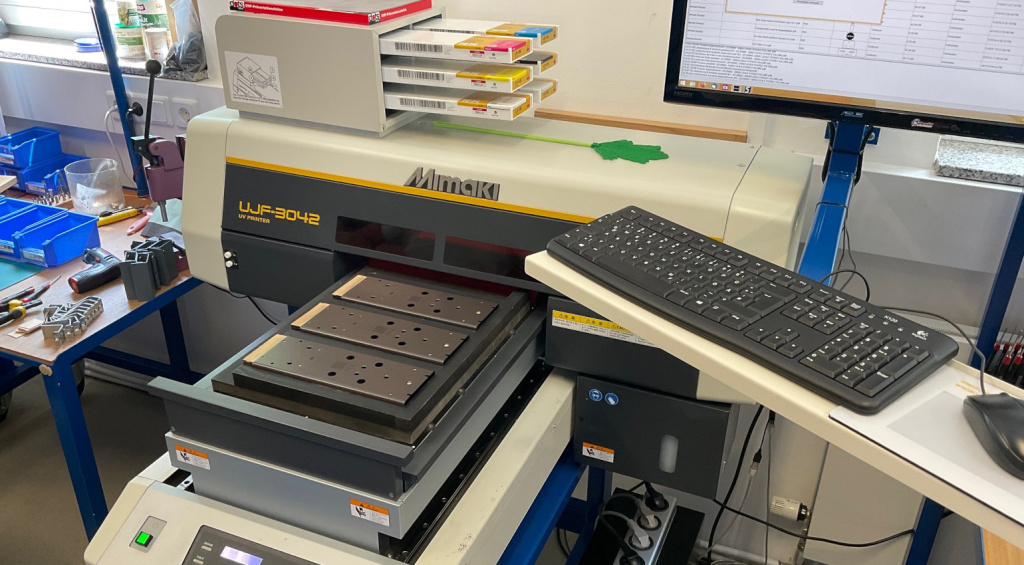

Lehle develops and manufactures its products entirely in Germany. Assembly, testing, and final inspection take place in the Lower Rhine region with the help of local suppliers. “Made in Germany” is more than just a label here; it’s part of a quality philosophy that encompasses reliability, repairability, and long-term availability.

Part 2: The Interview

To understand why Lehle works this way and why signal flow is a physical, not philosophical, question for Burkhard Lehle, I spoke with him at length.

Jan: “Burkhard, your story starts out surprisingly unspectacular. How did it really begin?”

Burkhard Lehle: “It actually started when my parents signed me up for guitar lessons. That was in the village where I grew up, when I was about ten. That led me to study music and physics in order to become a teacher. However, during my studies, I realized that I didn’t want to be a teacher after all. So, I started repairing guitars and amplifiers.”

“In the beginning, there’s often no grand plan – just a very specific problem.”

Jan: “You then ran a repair shop for several years. How important was that time for what later became Lehle?

Burkhard: “Very important. I ran a repair shop full-time for three years. It was extremely educational because you’re confronted with very real problems on a daily basis. After that, I looked for a product that I could manufacture myself, for pragmatic reasons, primarily. A shop with fixed opening hours isn’t particularly family-friendly.”

Jan: “The famous first Lehle switcher came about rather by chance, didn’t it?”

Burkhard: “Yes, absolutely. That was in 1998. A customer came into the shop wanting a switcher for two amps that wouldn’t hum. It wasn’t a major product idea, just a specific problem. That’s exactly how it all started.”

“Products aren’t created by marketing; they’re created by demand.”

Jan: “What were your initial expectations for these products?”

Burkhard: “My personal goal has always been to build useful products. If I already own several amplifiers, it makes more sense to use them together than to buy an additional one. At the same time, products must be durable and, ideally, repairable. Over time, design also became an important issue, but always as part of the function.”

Jan: “Among us guitarists, Lehle is often associated with signal flow. Why is this so important to you?”

Burkhard: “We don’t just make products for guitarists. Other stringed instruments and sound generators also play a role for us. But basically, it’s always the same process: a string vibrates, producing an electrical signal, which is subject to clear physical and electronic rules.”

Jan: “Where do you think most problems arise?”

Burkhard: “The longer and more complex a signal network becomes, the more factors you have to take into account. We believe that the signal coming from the instrument should be preserved as much as possible. If a rig is not understood as a fragile system and is instead assembled like a set of building blocks, then at some point, only a trickle of the original signal remains. And you can hear that.”

Jan: “At the same time, awareness of this issue seems to be growing.”

Burkhard: “Yes, I agree. More and more musicians are concerned with good signal flow. We can also see this in our sales figures, which, apart from the slump caused by the Coronavirus pandemic, have been rising steadily for years.”

“If the rig isn’t a system, you lose the sound along the way.”

Jan: “If you wanted to talk about ‘Lehle DNA,’ how would you describe it?”

Burkhard: “Simple, straightforward, and stable. Functionality is always the priority. For us, the product comes first, then the text. We stick very closely to technical facts. Voodoo mojo, storytelling, or hype – that’s not our thing.”

Jan: “Lehle products are considered extremely reliable. What technology is behind this?”

Burkhard: “We analyze the weak points of mechanical components, such as potentiometers and switches, and anything else that moves. Where possible, we replace them with wear-free solutions. For example, we use VCAs instead of potentiometers and Hall sensors instead of mechanical designs. Our push buttons, used with relays, have been in use for almost 25 years. Ultimately, customers should be able to rely on our devices to work, whether they’re using them on a stadium stage, in a club, or at home.”

“The transformer posed risks, both technical and economic, but they were necessary.”

Jan: “Was there a particular challenge with the product?”

Burkhard: “Definitely the high-impedance transformer. I had to delve deeply into physics for that one. The biggest problem was that there was no market for electric guitar transformers. We either have components specially manufactured for us or use components intended for completely different applications. We built many samples and sample series while working with limited financial resources. Today, this transformer is at the heart of about a third of our products.”

Jan: “If you had to name three Lehle products that are particularly helpful to guitarists, which ones would they be?”

Burkhard: “First and foremost, the LEHLE P-SPLIT III because it contains our transformer, is passive and reliable, and unobtrusive. Second, the LEHLE MONO VOLUME or MONO VOLUME S – the hall sensor technology with VCA is wear-free and extremely reliable. Thirdly, the LITTLE LEHLE III. It’s a real multitool: AB switcher, effects looper, and mute button. The possible applications are enormous.”

Jan: “Speaking of possible applications: What problems do your products solve that many guitarists aren’t even aware of?”

Burkhard: “Definitely signal loss and ground loops. You can immediately hear ground loops, but signal loss creeps up on you. Often, you only realize it when you plug the instrument directly into the amp, and suddenly, your eyes and ears open up. Then the troubleshooting begins – and often ends up with us.”

“You only notice signal loss when it’s suddenly gone.”

Jan: “You work with many artists. Are there any anecdotes that have particularly stuck in your memory?”

Burkhard: “There are many. We have a soft spot for anything outside the mainstream, such as the sound installations by Sunn O))) or Ui-Kyung Lee‘s composition for two guitars and four Lehle volume pedals. But one of my favorite stories is quite pragmatic. At the end of the Marsimoto show, the technician placed a LEHLE P-SPLIT on the keyboard keys so that the band could leave the stage while the keyboard continued to play.”

Jan: “Yet you don’t offer custom-made products. Why?”

Burkhard: “Custom solutions always carry the risk of losing track of costs. If such a device breaks down, it gets complicated. Standard devices have been tested thousands of times and can be quickly replaced worldwide. That’s why we rely on flexible tools that can be combined depending on the application. Rigid custom solutions often end up collecting dust in the basement for years.”

“Flexibility doesn’t come from custom solutions, but from smart tools.”

Jan: “Finally, what are you most proud of personally when you look at Lehle?”

Burkhard: “Definitely my team. We have grown together over the years, overcoming many challenges. Currently, we are even building a new company building on our own. Despite issues such as US tariffs, we have continued production and increased sales. You can only achieve something like that together.”

Jan: “Thank you for talking to us, Burkhard – and of course, good luck in 2026!”

This article was originally written by Jan Rotring for GEARNEWS.de.

*Note: This article about Lehle GmbH contains affiliate links that help finance our site. Rest assured, the price for you always remains the same! If you buy something through these links, we receive a small commission. Thank you for your support!

One response to “Lehle Interview: Signal Flow Made in Germany.”

2,5 / 5,0 |

2,5 / 5,0 |

This article seems like a response to Walrus Audio releasing their new volume pedal which borrows ideas and technologies from the Telonics FP-100 and the Lehle Volume pedals.

Walrus Audio is notorious for borrowing ideas from other companies’ already successful products and undercutting them on price. They’ve done that to the Pinstripe Pedals DISO+ and the Strymon Night Sky, Meris Mercury 7, Hologram Electronics Microcosm and more!

Look out innovative pedal companies… you may be next.